BISAC NAT010000 Ecology

BISAC NAT045050 Ecosystems & Habitats / Coastal Regions & Shorelines

BISAC NAT025000 Ecosystems & Habitats / Oceans & Seas

BISAC NAT045030 Ecosystems & Habitats / Polar Regions

BISAC SCI081000 Earth Sciences / Hydrology

BISAC SCI092000 Global Warming & Climate Change

BISAC SCI020000 Life Sciences / Ecology

BISAC SCI039000 Life Sciences / Marine Biology

BISAC SOC053000 Regional Studies

BISAC TEC060000 Marine & Naval

The surfaces of building materials of hydrotechnical constructions undergo the process of algae biofouling. The degree of damage depends on the environmental factors that are affect-ed by the level of anthropogenic load areas. Modeling the biofouling process of concrete with algae under laboratory conditions has allowed determining their impact on the building ma-terial, accompanied by changes in chemical and mineralogical composition of the surface of products. The microscopic examination of sample’s surfaces and evaluation of the effective-ness of various ions leaching from building materials shows the results of "algal attack" relat-ed to the acceleration of biodegradation of materials under the influence of aggressive meta-bolic products, mechanical action neoplasms, creating optimal conditions for the development of subsequent aerobic microbial decomposers. To clarify the nature of chemical processes in the system “algocenosis – concrete” the changes of chemical and phase (mineralogical) com-position of the surface layer of concrete sample were studied. The effect that algae produce on hydraulic engineering constructions is due to the fact that these organisms, belonging to phototrophs and standing at the beginning of the food chain, initiate new microbial growth.

biofouling, hydrotechnical constructions, algae, building material, biofilm matrix.

I. Introduction

Materials used in the marine environment are prone to the phenomenon of biofouling. The problem of hydrotechnical constructions biofouling is one of the main issues of the Russian seas environmental security. Seawater contains up to 107 viruses, 106 bacteria, 103 fungi, 103 microalgae, and 10 to 100 microscopic larvae and spores per ml [1-5], so the biofouling rate is very high.

Within minutes of immersing a clean surface in water it adsorbs a molecular ‘conditioning’ film, consisting of dissolved organic material. Bacteria colonize within hours, as may unicellular algae and cyanobacteria (blue-green algae). These early small colonizers form a biofilm: an assemblage of attached cells sometimes referred to as ‘microfouling’ or ‘slime’[6].

In general, the complex process of biofouling follows an identifiable progression from a purely physical to mostly biological process in four main phases: biochemical conditioning; bacterial colonization; unicellular eukaryote colonization; multicellular eukaryote colonization [7].

Algae are the main element of coastal ecosystems, so they predetermine the succession phases in the fouling communities. Being the autotrophic organisms, they are the first to appear on the surface of building materials and develop in large amounts, giving rise to various food chains and creating conditions for the existence of other autotrophic and heterotrophic organisms, accelerating biodeterioration processes mostly due to excretion of corrosive substances in the process of metabolic activity [7-10].

As a result of the organisms’ life activity and dying-off the physical, chemical and organoleptic properties of water deteriorate, the objectionable odors appear. The appearance of increased biomass concentration areas results in the development of heterotrophic organisms, which affects the materials of the structures’ surface, causing biocorrosion. Biofilm is comprised of several microorganisms’ layers, covered with complex polymeric structure – extracellular polymer substances. The structure of biofilm is amorphous and gelatinous, its constituents are polysaccharides, proteins etc. The process of biological fouling is often grouped in the literature into key growth stages which include an initial accumulation of adsorbed organics, the settlement and growth of pioneering bacteria creating a biofilm matrix and the subsequent succession of micro and macrofoulers [11].

The biofouling of hydrotechnical constructions and equipment surface, immersed repeatedly or constantly in water, is a serious problem, as the presence of sessile microbiota on the surface results in considerable decrease of the equipment technical characteristics, provides extra load on constructions and structures and accelerates considerably the process of material damage.

In conditions, favorable for biofouling, the construction products’ surface is attacked by a range of various organisms, and deterioration of materials, including concrete, goes on at a quick rate forming the favorable conditions for agents, characterized by aggressive type of action (chemolithotrophic bacteria and micromycetes). These agents can leach out the mineral matrix which results in the compound’s weakening.

The purpose of research, the findings of which are presented in this work, consisted in discovering and identifying algae on hydrotechnical constructions’ damaged surfaces, studying the chemical processes, which proceed on the surface of building materials as a result of «biological action», as well as the laboratory testing of means to protect structures.

II. Materials, conditions and methods of research

The object of research was the samples of materials of hydrotechnical constructions damaged surfaces, and the model samples of cement-and-sand concrete. The samples of building materials with biofouling were a source of obtaining mixed and pure algae cultures on various mineral growth media by means of wipe-sampling and cultivation in the climate chamber with illumination [8-10]. The pure cultures were obtained by dilution method and the subsequent cultivation on solid growth media.

III. The results of the experiments

The carried-out examination of constructions has demonstrated the visual traces of concrete surfaces' colonization with algae.

After placing the wipe-samples on solid growing media the representatives of the following groups of algae were identified: diatomic algae (Bacillariophyta), blue-green algae (Cyanophyta); green algae (Chlorophyta) and yellow-green algae (Xanthophyta), but the species diversity of surface algocenosis in the researched areas varied depending on the functional purpose of the area or on the anthropogenic load level. The dominant species in the vast majority of samples were blue-green and diatomic algae. Diatoms are protists belonging to phylum Bacillariophyta and class Bacillariophyceae. Their cell walls are shaped like tiny glass pillboxes, with an amazing array of sizes, shapes and ornamentation. The rigid silicate frustule encases the vegetative protoplast [14].

The blue-green algae in the samples were presented mostly by Chloroococcales and Oscillatoriales. First of all, there were observed the mucoid colonies of randomly located spherical cells of genus Microcystis, and the spherical, sometimes ellipsoid, forms of genus Gloeocapsa. The latter are characterized by high resistance to the environmental temperature alterations, propagate rapidly even at subzero temperatures, hidden in the cracks of building materials [9, 10]. Apart from unicellular blue-green algae, the filamentous blue-green algae were also discovered on the biofouling areas of hydrotechnical constructions, mostly the representatives of two genera of the order Oscillatoriales: Oscillatoria and Phormidium.

One of the most important properties of blue-green algae is the release of mucus around the cells, presented by exopolysaccharides. The mucus of colonies and the mucous axilla of filamentous algae form a good protective skin, protecting the cells against the adverse effects of the environment [9]. Besides, mucus provides the efficient fixing of cells on the building materials surface.

In the wipe-samples from the surfaces the diatomic algae, belonging to the order Naviculales, genera Pinnularia, Nitzschia and Navicula were discovered. It must be mentioned that this very group of algae was the most sensible to drying.

Green algae are presented by various species, but the predominant species is Pleurococcus sp. Besides, on the surface of building constructions the unicellular green algae, and among them - Chlorella, Scenedesmus, Pleurococcus etc, were discovered.

Among the blue-green algae there were species, which combine photosynthesis and the ability to absorb atmospheric nitrogen, which increases their relative trophic independence and allows them to be the first to colonize building materials surfaces, creating conditions for other organisms' development, which need various sources of nitrogen.

The obtained selective cultures of diatomic, blue-green and green algae were used for the laboratory study of biofouling processes on the surface of concrete samples in liquid media of tailored composition.

The results of determining the content of the main chemical elements (in terms of ions amount) in the surface layer of concrete samples after the two-month keeping of algae in the growing medium and in the tap water are presented in tab. 1.

From the data in tab. 1 we can see, that at the green and blue-green algae development on concrete samples’ surface the Ca2+ and SO42- ions are leached out to the highest extent. The intense leaching of calcium is conditioned by the acidic metabolites, produced by algae: carbon dioxide and organic acids. Discharging these metabolites, the algae normalize the pH level, which contributes to their further penetration inside the concrete.

The biofouling conditions contribute to the leaching of most of ions out of concrete, except for phosphate ions, which are bound in material. The concrete’s losing of a large amount of sulfate ions is rather conditioned by the decrease of Ca2+ concentration, bound with СО2, and by leaching of Na+ and K+ ions, which contribute to sulfates solubilization. The silicate ions are also leached out, which can result in appearance and development of diatoms. So, the algocenosis not only altered considerably the composition of the concrete surface layer, but also formed the favorable mineral medium for other microorganisms.

Table 1. The chemical composition of the concrete samples surface layer, weight content%

(data for 100%)

|

Ion |

Medium |

|

|

water without algae (test sample) |

growing medium with algae |

|

|

51.03 |

45.51 |

|

|

Si4+ |

33.43 |

37.48 |

|

SO42- |

5.231 |

3.729 |

|

Al3+ |

4.159 |

4.994 |

|

Fe3++Fe2+ |

3.139 |

3.887 |

|

Mg2+ |

1.166 |

1.232 |

|

K+ |

1.146 |

1.889 |

|

Na+ |

0.2517 |

0.3859 |

|

Mn2+ |

0.0939 |

0.1050 |

|

Zn2+ |

0.0377 |

0.0338 |

|

PO43- |

0.3156 |

0.7563 |

The findings of the experiment confirm the transformation of Ca(OH)2 to CaCO3 (fig. 1) if there are algae on the concrete surface. Apart from this process, the algae metabolites catalyze the hydration of residual clinker minerals (Ca3SiO5, Ca2SiO4) to crystalline hydrosilicates, which is confirmed by crystalline phases calculation (tab. 2), carried out by means of powder diffraction patterns modelling.

Table 2. Evaluation of the concrete samples surface layer phase composition, %

|

Mineral |

Experimental conditions |

||

|

water |

Chu medium №10 |

Drew medium |

|

|

Quartz (SiO2) |

57.5 |

65.6 |

65.2 |

|

Portlandite (Ca(OH)2) |

32.9 |

- |

- |

|

Calcite (CaCO3) |

4.9 |

26.7 |

30.5 |

|

Hatrurite (Ca3SiO5) |

1.6 |

- |

- |

|

Larnite (Ca2SiO4) |

1.6 |

0.7 |

- |

|

Scawtite (Ca7(Si6O18)CO3·2H2O) |

- |

5.8 |

- |

|

Gismondine (CaAl2Si2O8·4H2O) |

1.5 |

1.2 |

4.3 |

The accumulation of calcite on the concrete surface in the algae medium (fig. 1) was observed during the microscopic studies of changes in samples, which confirmed the previously noted fact of the presence of carbonates on concrete surfaces, colonized by algae [1, 9, 10].

Fig. 1. Minerals on the samples’ surface

It has been determined that after 60 days the strength of samples, kept in the medium with blue or blue-green algae, was almost not reduced; the mass increased in some cases, sometimes up to 10%, mostly due to the calcium leaching out of concrete with the subsequent formation of calcite.

In the media where diatomic algae with hard silicate membranes are predominant, the mass of samples was increasing with the process of biofouling. At this, the strength was increased, too, probably due to the fact that pores and microfissures were filled with calcite and with hydration products of residual clinker minerals.

So, the concrete structures in conditions favorable for biofouling require the special protection, in order to provide the ecological safety of hydrotechnical constructions functioning to full extent. To provide such protection a method of treating concrete with sol-gel mixtures was suggested.

The biocidal criterion of the designed sol-gel mixture was the percentage of killed microorganism cells on its surface, which was calculated from the ratio of live and killed cells after the microscopic examination of the sample, stained with vital dye. The test sample was a variant of coating, containing no biocidal component.

The findings of the experiment are given in tab. 3.

Table 3. The percentage of killed bacteria and algae on the surface of coating with biocidal component

|

Type of coating |

Type of biological model system |

||

|

Green algae |

Bacteria |

Biocenosis, including algae and bacteria |

|

|

Sol-gel coating with biocidal component |

40-50% |

0-10% |

10-20% |

|

Coating without additive |

0-10% |

0-10% |

0-5% |

On the basis of experimental data (tab. 3), we can arrive at the conclusion that due to the adding of biocidal component the coating prevents bacteria and algae development. The most sensitive were green algae, the percentage of their destruction reached 50%. In a biocenosis, containing both algae and bacteria, this value reduced to 20%. This can be due, as it was stated earlier [9, 10], to the consolidation of microorganisms’ conglomerates as a result of a similigley substance generation by bacteria; this substance seemingly protects the organisms against the biocide action.

On the surface of the coating the microorganisms were not killed. It was determined that the pure sol-gel coating (without additive) provides a slight biocidal action on microorganisms by itself (the percentage of cells destruction is 0-10%), which is within the framework of statistical discrepancy.

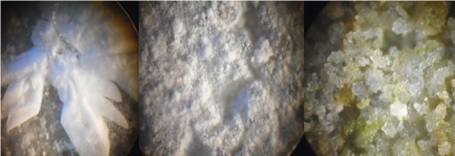

At creating products with coating the sol-gel was placed on the surface of concrete cubes by means of dipping method. The samples of building materials were placed to the media, simulating the conditions of submerged bacteria and algae cultivation, after which they were kept in the favorable for microorganisms’ development conditions within a month. After the experiment the state of samples under study was evaluated visually (wholeness, new formations, the level of surface’s biofouling with microorganisms), by mass content and strength alteration.

Results of the visual examination of samples after the experiment are shown in tab. 4.

The biofouling level of the concrete samples with coating, placed into the medium with algae didn’t exceed 25%, while for the test sample it amounted to 70-75%.

It was determined that the surfaces of samples without coating in all the considered cases were characterized by more changes, than the samples with coatings. These alterations are due to the presence of the above mentioned new formations of various crystalline structures. A certain mass increase of the samples without coating (sometimes up to 10%) was also conditioned by crystal formation. In the variants with biocidal coating such phenomena were virtually not observed.

Table 4. Concrete samples, kept in model media

The integrity damage of samples was confirmed also by the alteration of рН value: when keeping the samples without coating in tap water the medium was more alkaline (рН= 10.5-11.0), which is probably conditioned by the more intensive leaching of Ca2+ due to the absence of coating in the model media with thionic, and to a lesser degree with nitrifying bacteria; the intensive leaching of Ca2+ ions to the solution due to the absence of coating was accompanied by encrustation of samples with calcium sulfate crystals (CaSO4·2H2O– calcium sulfate dihydrate) and other crystalline and amorphous compounds, and a certain decrease of рН value (5.9-8.0); the alkaline medium (рН 8.9-9.3) in the algae culture medium, where corrosion is less intensive, coheres with the low amount of the appearing crystalline formations.

The strength tests of samples have shown that even without any special processing or keeping in model media the samples, covered with sol-gel coating containing a biocidal component, is characterized by strength about 15% higher, than for samples without coating. More than that, the samples, covered with sol-gel coating, after keeping them within two months in model media, are more often characterized by the higher strength (by 30-100%), than the samples without coating, placed in the same model solutions.

Comparing the strength of samples without sol-gel coating, we can say that the most notable strength loss of samples is observed at the action of nitrifying and thionic bacteria (up to 25%).

IV. Conclusion

It must be mentioned that the coating makes the microorganisms’ development inside the bulk of concrete impossible, and thus reduces considerably the amount of microgerms in a volumetric unit of the environment and prevents the development of organisms on the surface due to the low adhesion level.

As a result of the carried-out research the makeup of biofouling algocenosis on hydrotechnical constructions’ concrete surfaces was determined. It was demonstrated that the biocenosis development is determined by a complex of environmental factors and weather conditions. The certain chemical processes, going on the surface of materials in the process of its deterioration under the action of algae, have been identified.

The high efficiency of using the sol-gel coating in conditions of biofouling has been demonstrated. The building materials with the protective coating would be less prone to biofouling and longer in service, and the hydrotechnical constructions would be less exposed to biocorrosion, which would result in their longer trouble-free service.

The article is prepared within the framework of implementing the project part of the state task of Assignment № 14.2406.2014/К.

1. J.J. Cole, “Interactions between bacteria and algae in aquatic ecosystems“, in Annu. Rev. Ecol. Syst., vol. 13, 1982, pp. 291-314.

2. P.R. Jensen, W.Fenical, “Strategies for the discovery of secondary metabolites from marine bacteria: ecological perspectives”, in Annu. Rev. Microbiol., vol. 48, 1994, pp. 559-584.

3. S. Engel, P.R. Jensen, W. Fenical, “Chemical ecology of marine microbial defense”, in J. Chem. Ecol., vol. 28, 2002, pp. 1971-1985.

4. T. Harder, “Marine epibiosis: concepts, ecological consequences and host defence”, in Marine and industrial biofouling, H.C. Flemming, P.S. Murthy, R. Venkatesan, K. Cooksey, Eds., Berlin: Springer, 2009, pp. 219-231.

5. F. Goecke, A. Labes, J. Wiese, J. F. Imhoff, “Chemical interactions between marine macroalgae and bacteria”, in Mar. Ecol. Prog. Ser., vol. 409, 2010, pp. 267-300.

6. M.E. Callow, J.A. Callow, “Marine biofouling: a sticky problem”, in Biologgist, vol. 49 (1), 2002, pp. 1-5.

7. M. Wahl, ”Marine epibiosis.I. Fouling and antifouling: some basic aspects”, in Mar. Ecol. Progr., vol. 58, 1989, pp. 175-189.

8. Th. Warscheid, J. Braams, “Biodeterioration of stone: a review”, in International Biodeterioration and Biodegradation, vol. 46 (4), 2000, pp. 343-368.

9. E.N. Goncharova, M.I. Vasilenko. “Algocenosis of the deteriorated urban buildings and constructions ” in Fundamental research, 8 ( 1), 2013, pp. 85-89.

10. E.N. Goncharova, M.I. Vasilenko, V.M. Nartsev, “The role of microalgae in the process of urban buildings deterioration”, in Bulletin of Belgorod State Technological University named after V.G.Shukhov, vol. 6, 2014, pp. 192-196.

11. N.A. Cutler, H.A. Viles, S. Ahmad, St. McCabe and B.J. Smith, “Algal ‘greening’ and the conservation of stone heritage structures” in Science of the Total Environment, vol. 442, 2013, pp. 152-164.

12. L.D. Chambers, K.R. Stokes, F.C. Walsh, R.J.K. Wood, “Modern approaches to marine anti-fouling coatings” in Surf. & Coat. Techn., vol. 201, 2006, pp. 3642-3652

13. D.Yu. Vlasov , M.S. Zelenskaya, “The development of micromycetes on lapideous substrate in experimental conditions” in Mycology and phytopathology, vol. 37 (6), 2003, pp.33-38.

14. A.Ch. Anil, J.S. Patil, S. Mitbavkar, P.M. D'Costa, Sh. D'Silva, S. Hedge et al., “Role of Dia-toms in Marine Biofouling”, in Rec. Adv. Appl. Asp. Ind. Mar. Alg., vol. 1, 2006, pp. 351-365.